The Perfect Recipe for Success: Discover the Advantages of Using an Auto French Fries Machine

Are you tired of spending hours peeling, cutting, and frying potatoes to make the perfect french fries? Look no further! Introducing the revolutionary Auto French Fries Machine, a game-changer in the world of fast food. This cutting-edge device takes all the hassle out of making french fries, allowing you to increase efficiency and reduce labor costs.

With its advanced technology and user-friendly interface, the Auto French Fries Machine ensures consistent results every time. Say goodbye to unevenly cooked fries and hello to perfectly golden and crispy goodness. Whether you own a restaurant, a food truck, or simply love hosting summer BBQs, this machine will take your culinary skills to the next level.

But that’s not all! The advantages of using an Auto French Fries Machine go beyond convenience. By automating the process, you can save valuable time and focus on other aspects of your business. Plus, with its customizable settings, you can cater to different customer preferences, ensuring customer satisfaction every bite of the way.

The advantages of using an auto French fries machine

When it comes to making french fries, using an auto French fries machine offers numerous advantages. Firstly, it eliminates the need for manual labor, saving you time and effort. Instead of spending hours peeling, cutting, and frying potatoes, you can simply load them into the machine and let it do the work for you. This not only increases efficiency but also allows you to allocate your staff’s time to other important tasks

Secondly, an auto French fries machine ensures consistent results. With its precise cutting and frying mechanisms, every fry comes out perfectly cooked and evenly golden. This consistency is crucial for businesses that strive to deliver high-quality food consistently. Customers will appreciate the uniformity and reliability of your fries, enhancing their dining experience and increasing their satisfaction.

Additionally, using an auto French fries machine can help you reduce costs. By automating the process, you minimize the risk of human error, which can lead to wastage of ingredients. With precise cutting and portioning, you can control the amount of potatoes used, reducing food waste. Moreover, the machine’s energy-efficient design can help lower your overall electricity consumption, contributing to cost savings in the long run.

How an auto French fries machine works

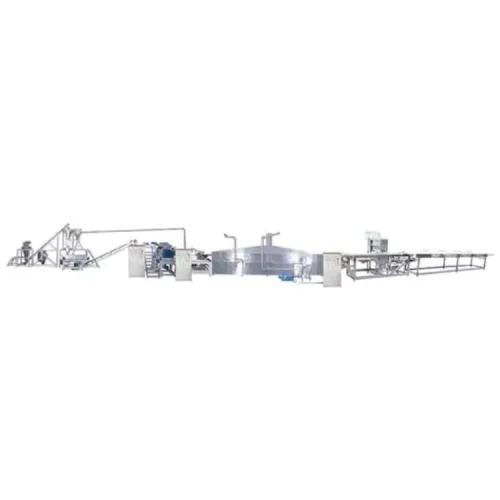

An auto French fries machine operates through a combination of mechanical and technological processes. Depending on the model, the machine may consist of different components such as a potato feeder, cutting mechanism, frying chamber, and a conveyor belt system. Let’s take a closer look at each step of the process.

- Potato Feeding: The machine is equipped with a potato feeder that holds a large quantity of potatoes. These potatoes are automatically fed into the cutting mechanism, eliminating the need for manual loading. This feature is particularly beneficial for high-volume establishments that require a constant supply of fries.

- Cutting Mechanism: Once the potatoes are fed into the machine, they pass through a cutting mechanism. This mechanism is designed to ensure precise and uniform cuts. The potatoes are sliced into consistent sizes, resulting in evenly cooked fries. The cutting mechanism can be adjusted to produce different fry shapes, allowing you to cater to various customer preferences.

- Frying Chamber: After the potatoes are cut, they are transferred to the frying chamber. This chamber is equipped with heating elements that maintain a consistent temperature for optimal frying. The fries are evenly distributed in the chamber, ensuring they cook uniformly. The frying time can be adjusted based on the desired level of crispiness.

Conveyor Belt System: Once the fries are cooked, they are transported out of the frying chamber using a conveyor belt system. This system ensures a smooth and continuous flow of fries, preventing any delays or interruptions in the production process. The fries are then collected in a tray or container, ready to be served.

Factors to consider when choosing an auto French fries machine

When selecting an auto French fries machine for your business, it’s important to consider several factors to ensure you choose the right one. Here are some key considerations to keep in mind:

- Capacity: Evaluate the capacity of the machine and determine if it aligns with your production needs. Consider the volume of fries you typically serve and choose a machine that can handle that level of output. It’s essential to strike a balance between efficiency and capacity to avoid delays or overworking the machine.

- Versatility: Look for a machine that offers versatility in fry shapes and sizes. Different customers may have varying preferences, so having the ability to cater to those can increase customer satisfaction. Some machines offer interchangeable cutting blades, allowing you to switch between different fry styles easily.

- Ease of use: Opt for a machine with a user-friendly interface and intuitive controls. The last thing you want is a complicated machine that requires extensive training to operate. Look for features such as touchscreen displays, preset programs, and easy-to-understand settings. This will enable your staff to quickly learn how to operate the machine, reducing the risk of errors and improving efficiency.

- Cleaning and maintenance: Consider the ease of cleaning and maintaining the machine. Look for features such as removable parts and dishwasher-safe components, which can streamline the cleaning process. Additionally, check if the machine requires any specific maintenance procedures or if it comes with a warranty or service package for added peace of mind.

Benefits of using an auto French fries machine for businesses

Implementing an auto French Fries Machine in your business can bring several benefits that can help drive success. Here are some advantages for different types of businesses:

- Restaurants: For restaurants, an auto French fries machine can significantly increase efficiency during peak hours. By automating the process, you can ensure a constant supply of perfectly cooked fries, reducing wait times for customers. This can improve overall table turnover rates and enhance the dining experience.

- Food Trucks: Food trucks often face limitations in terms of space and resources. An auto French fries machine can help food truck owners maximize their operations by minimizing the space required for manual cutting and frying. With its compact design and efficient output, the machine can streamline the production process, allowing food truck operators to serve more customers in less time.

- Catering Services: When catering events, timing is crucial. An auto French fries machine can simplify the preparation process, allowing caterers to focus on other aspects of the event. With consistent and high-quality fries, you can impress your clients and ensure their guests are satisfied with the food.

- Home Use: Even for individuals hosting small gatherings or summer BBQs, an auto French fries machine can be a game-changer. It eliminates the need for manual labor, freeing up your time to socialize with your guests. You can impress them with perfectly cooked fries without the stress and effort of traditional methods.

Maintenance and cleaning tips for auto French fries machines

To ensure the longevity and optimal performance of your auto French fries machine, regular maintenance and proper cleaning are essential. Here are some tips to keep in mind:

- Daily cleaning: After each use, remove any leftover potato debris from the cutting mechanism and frying chamber. Most machines have removable parts that can be easily cleaned. Use warm water and mild detergent to clean these parts thoroughly. Avoid using abrasive cleaners or scrubbers that may damage the machine’s surfaces.

- Weekly deep cleaning: Perform a more thorough cleaning at least once a week. Disassemble the machine as per the manufacturer’s instructions and clean each component individually. Pay special attention to hard-to-reach areas to remove any buildup of grease or debris. Ensure all parts are completely dry before reassembling the machine.

- Regular maintenance: Follow the manufacturer’s guidelines for regular maintenance tasks such as lubricating moving parts or replacing worn-out components. Keep a record of maintenance activities to track when certain tasks need to be performed. Regular maintenance can help prevent breakdowns and ensure the machine operates smoothly.

- Store properly: When not in use, store the machine in a clean and dry environment. Protect it from dust, moisture, and extreme temperatures. Cover the machine with a fitted cover or use a dedicated storage area to prevent any damage.

FAQs

An auto French fries machine is a device designed to automate the process of slicing and frying potatoes to make French fries. It typically includes features such as potato loading, cutting, frying, and sometimes seasoning.

Auto French fries machines typically work by first loading potatoes into a hopper. Then, the machine slices the potatoes into fries of uniform size. These fries are then automatically conveyed into a frying chamber where they are fried until golden brown. Finally, the fries are usually dispensed onto a conveyor belt for packaging or serving.

- Efficiency: These machines can process large quantities of potatoes quickly, increasing production rates.

- Consistency: The automation ensures that fries are cut to uniform sizes and fried consistently, resulting in a uniform product.

- Labor-saving: By automating the process, businesses can reduce the need for manual labor, saving time and costs.

- Hygiene: Many auto French fries machines are designed with easy-to-clean surfaces, enhancing hygiene standards in food production environments.

- Capacity: Consider the volume of potatoes you need to process to choose a machine with an appropriate capacity.

- Size and space requirements: Ensure the machine fits within your workspace and has adequate space for operation and maintenance.

- Features: Evaluate the features offered by different machines, such as cutting options, frying methods, and additional functionalities.

- Budget: Determine your budget and compare prices and capabilities to find the best value for your investment.

- Maintenance and support: Look for machines that are easy to clean and maintain, and consider the availability of technical support and spare parts.

Yes, most auto French fries machines can process various types of potatoes, including different sizes and varieties. However, it's essential to check the specifications of the machine to ensure compatibility with the types of potatoes you intend to use.

While some familiarity with the machine's operation may be necessary, many auto French fries machines are designed for intuitive use and come with user manuals or training materials. Training may be provided by the manufacturer or distributor to ensure safe and efficient operation.