The Ultimate Guide to Choosing the Perfect Spice Coating Machine for Your Business

Are you in the food industry and looking for the perfect spice coating machine to take your business to the next level? Look no further! In this ultimate guide, we will walk you through the essential factors to consider when choosing a spice coating machine for your business.

Gone are the days of manually coating spices on your products. With the right spice coating machine, you can streamline your production process, increase efficiency, and ensure consistent flavor across every product. But with so many options available in the market, how do you make the right choice?

In this comprehensive guide, we will discuss the various types of spice coating machines, their features, and how they can benefit your business. We will also delve into important considerations such as production capacity, ease of use, maintenance, and cost-effectiveness. Whether you’re a small-scale producer or a large-scale manufacturer, this guide is designed to help you make an informed decision.

Ready to spice things up in your business? Let’s dive in and discover the perfect spice coating machine for your unique needs.

In terms of capacity, you need to assess the volume of chicken you typically grill in a day or during peak hours. This will help you determine the size of the griller machine you require. It’s essential to choose a griller with enough capacity to handle your restaurant’s demand without causing delays or compromising on the quality of the grilled chicken.

Benefits of Using a Spice Coating Machine

Using a spice coating machine offers a multitude of benefits for your business. Let’s take a closer look at some of the key advantages:

- Increased Efficiency: One of the biggest advantages of using a spice coating machine is the significant increase in efficiency. Manual coating can be time-consuming and labor-intensive, leading to slower production rates. By automating the process, a spice coating machine can coat a large number of products in a short amount of time, allowing you to meet customer demands more effectively.

- Consistent Flavor: When manually coating spices, it can be challenging to achieve consistent flavor across all products. The amount of spice applied may vary from batch to batch, resulting in an inconsistent taste experience for your customers. With a spice coating machine, you can ensure that each product receives the same amount of spice, resulting in a consistent flavor profile that customers will come to love and expect.

- Reduced Waste: Precise control over the amount of spice applied is another advantage of using a spice coating machine. With manual coating, there is a higher chance of over or undercoating, leading to wastage of spices and uneven flavor distribution. With a machine, you can accurately measure and control the amount of spice applied, minimizing waste and maximizing cost-effectiveness.

- Improved Food Safety and Hygiene: Spice coating machines are designed with food safety and hygiene in mind. They are typically made from food-grade materials and incorporate features such as easy cleaning and sanitization. By using a machine, you can ensure that your products meet the highest standards of food safety, reducing the risk of contamination and maintaining the trust of your customers.

Types of Spice Coating Machines

Spice coating machines come in various types, each offering unique features and capabilities. Understanding the different types will help you choose the one that best suits your business needs. Here are the most common types of spice coating machines:

- Drum Coating Machines: Drum coating machines are widely used in the food industry for coating a variety of products, including nuts, snacks, and confectioneries. They consist of a rotating drum that tumbles the products while a spray system applies the spice coating. This type of machine ensures uniform coating and can handle large production volumes. It is suitable for businesses with high output requirements.

- Fluidized Bed Coating Machines: Fluidized bed coating machines utilize the principle of fluidization to apply a thin and even spice coating. The products are placed on a perforated bed, and air is blown through the bed to create a fluidized state. The spice coating is then sprayed onto the products, and the fluidized air helps distribute the spice evenly. This type of machine is ideal for delicate products and can provide precise control over the coating thickness.

- Batch Coating Machines: Batch coating machines are designed for smaller production volumes and are suitable for businesses with a diverse product range. They consist of a rotating drum or vessel where the products and spice coating are placed together. The rotation of the drum ensures even distribution of the spice coating. Batch coating machines are versatile and can handle various product sizes and shapes.

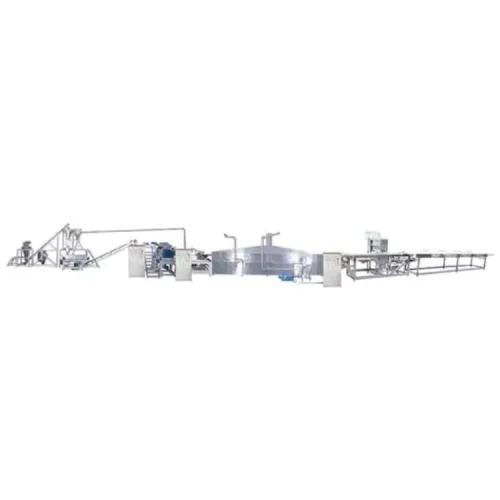

- Continuous Coating Machines: Continuous coating machines are designed for high-speed and continuous production lines. They are commonly used in large-scale manufacturing facilities. These machines offer high throughput and efficiency, making them ideal for businesses with high-volume production requirements. Continuous coating machines can be customized to meet specific product and process requirements.

Factors to Consider When Choosing a Spice Coating Machine

Selecting the right spice coating machine for your business is crucial to ensure optimal performance and long-term success. Here are the key factors you should consider before making a decision:

Capacity and Production Requirements

The first step in choosing a spice coating machine is to determine your production capacity and requirements. Consider the volume of products you need to coat per hour or per day. This will help you determine the size and capacity of the machine you need. It’s essential to choose a machine that can meet your current production demands and allow room for future growth.

Coating Quality and Consistency

Coating quality and consistency are critical factors to consider when selecting a spice coating machine. Look for a machine that can provide a uniform and even spice coating on your products. The machine should offer precise control over the amount of spice applied to ensure consistent flavor across all batches. Additionally, consider the texture and appearance of the coated products. The machine should be capable of achieving the desired coating texture and visual appeal.

Ease of Operation and Maintenance

Another crucial consideration is the ease of operation and maintenance of the spice coating machine. Look for a machine that is user-friendly and intuitive to operate. It should have clear instructions and controls that are easy to understand. Additionally, consider the cleaning and maintenance requirements of the machine. Look for features such as easy disassembly and cleaning, as well as access to spare parts and technical support.

Safety Features and Compliance with Regulations

Food safety is of utmost importance in the food industry. When choosing a spice coating machine, ensure that it meets the necessary safety standards and regulations. Look for features such as safety interlocks, emergency stop buttons, and proper guarding to prevent accidents and injuries. Additionally, consider any specific regulations governing the use of spice coating machines in your region or industry and ensure that the machine complies with those requirements.

Now that you have a good understanding of the key factors to consider, it’s time to evaluate the cost-effectiveness of the spice coating machine.

Factors to Consider When Choosing a Spice Coating Machine

Selecting the right spice coating machine for your business is crucial to ensure optimal performance and long-term success. Here are the key factors you should consider before making a decision:

Capacity and Production Requirements

The first step in choosing a spice coating machine is to determine your production capacity and requirements. Consider the volume of products you need to coat per hour or day. This will help you determine the size and capacity of the machine you need. It’s essential to choose a machine that can meet your current production demands and allow room for future growth.

Coating Quality and Consistency

Coating quality and consistency are critical factors to consider when selecting a spice coating machine. Look for a machine that can provide a uniform and even spice coating on your products. The machine should offer precise control over the amount of spice applied to ensure consistent flavor across all batches. Additionally, consider the texture and appearance of the coated products. The machine should be capable of achieving the desired coating texture and visual appeal.

Ease of Operation and Maintenance

Another crucial consideration is the ease of operation and maintenance of the spice coating machine. Look for a machine that is user-friendly and intuitive to operate. It should have clear instructions and controls that are easy to understand. Additionally, consider the cleaning and maintenance requirements of the machine. Look for features such as easy disassembly and cleaning, as well as access to spare parts and technical support.

Safety Features and Compliance with Regulations

Food safety is of utmost importance in the food industry. When choosing a spice coating machine, ensure that it meets the necessary safety standards and regulations. Look for features such as safety interlocks, emergency stop buttons, and proper guarding to prevent accidents and injuries. Additionally, consider any specific regulations governing the use of spice coating machines in your region or industry and ensure that the machine complies with those requirements.

Now that you have a good understanding of the key factors to consider, it’s time to evaluate the cost-effectiveness of the spice coating machine.

FAQs

A spice coating machine is a piece of equipment used in the food processing industry to apply a coating of spices, seasonings, or other flavorings to food products such as snacks, nuts, or fried items.

Spice coating machines typically consist of a rotating drum or tumbler where the food product is placed. The spices or seasonings are added to the drum, and as it rotates, the food product is evenly coated with the flavorings.

Spice coating machines can be used to coat a variety of food products, including nuts, chips, snacks, popcorn, fried foods (such as chicken or fish), and more.

Some benefits of using a spice coating machine include:

- Consistent flavor distribution: Ensures even distribution of spices or seasonings on the food product.

- Increased efficiency: Speeds up the coating process compared to manual methods.

- Cost savings: Reduces waste by minimizing excess seasoning usage.

- Customization: Allows for the adjustment of coating thickness and flavor intensity according to preference.

When selecting a spice coating machine, it's essential to consider factors such as production capacity, the type of food products to be coated, ease of cleaning and maintenance, automation features, and budget constraints.

Yes, many spice coating machines offer customization options to accommodate different food products and coating requirements. This can include adjustable speed settings, tilt angles, and variations in drum size and design.