Dough Ball Cutting Machine Revolutionizing the Baking Industry

Dough ball cutting machine has emerged as a game-changer in the food processing and bakery industry. As bakeries and food manufacturers strive for efficiency, consistency, and precision, these machines offer a reliable solution for producing uniform dough balls, a key ingredient in countless baked goods. In this comprehensive article, we will explore the features, benefits, types, and innovations in dough ball cutting machines, explaining why they have become an essential tool in modern food production.

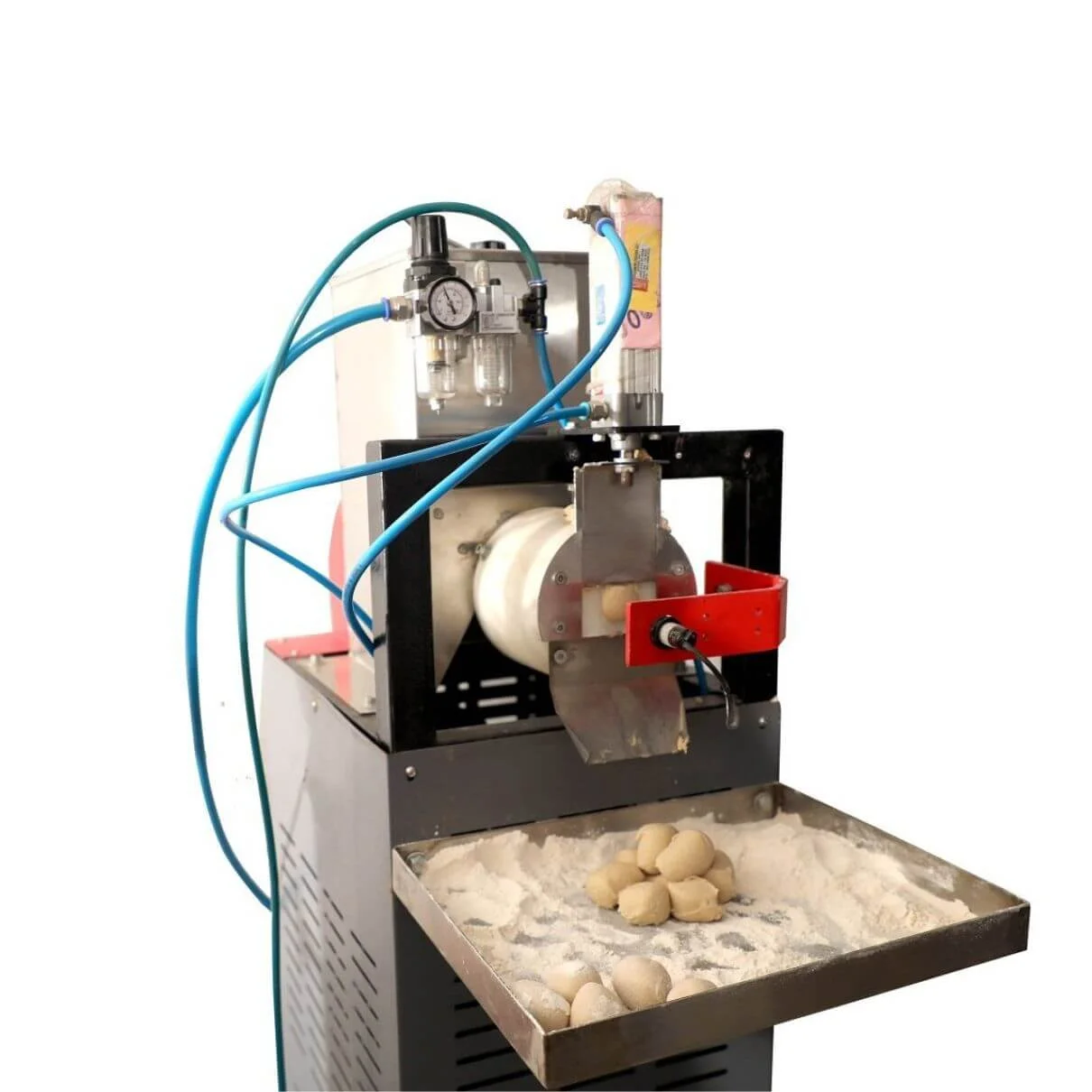

How Does a Dough Ball Cutting Machine Work?

The working principle of the dough ball cutting machine is relatively simple, yet incredibly effective. The machine generally follows these steps:

- Dough Feeding: Dough is fed into the machine either manually or via a conveyor belt.

- Dough Portioning: The machine uses a cutting mechanism—usually a rotating blade, auger, or hydraulic system—to divide the dough into predetermined portions.

- Ball Formation: After the dough is portioned, the dough pieces are rounded into uniform balls using a set of rollers or molds.

- Discharge: The finished dough balls are discharged onto a conveyor belt or tray for further processing, such as proofing, baking, or freezing.

Benefits of Using a Dough Ball Machine

- Improved Efficiency

One of the most significant advantages of using a dough ball cutting machine is the drastic improvement in production efficiency. Automated dough portioning speeds up the entire dough preparation process, allowing bakeries to produce large quantities of dough balls in a fraction of the time it would take manually. This efficiency translates into higher production and greater profitability.

- Consistency and Precision

Dough ball cutting machines are excellent at delivering uniform portions every time. By eliminating human error, these machines ensure that every dough ball is of the same size and weight, contributing to a consistent product. This is especially important for businesses that rely on consistency to maintain their reputation and customer trust.

- Cost-Effective

While the initial investment in a dough ball cutting machine may seem high, the long-term benefits far outweigh the costs. Automated systems reduce the need for manual labor, cutting down on operational costs and minimizing the risk of mistakes that could lead to waste. Additionally, the increased production speed and consistency often result in better resource management and higher returns on investment (ROI).

- Hygiene and Safety

Automating the dough ball cutting process reduces human contact with the dough, which improves hygiene standards and reduces the risk of contamination. Many modern machines are designed with easy-to-clean components and surfaces that comply with health and safety regulations, ensuring that bakeries maintain the highest cleanliness standards.

Types of Dough Ball Machines

There are different types of dough ball cutting machines, each of which is designed to meet specific production needs. Below are the most common types:

- Manual Dough Ball Cutting Machines

Manual dough ball cutting machines are suitable for smaller operations where the volume of dough is relatively low. These machines require manual input for dough feeding, and the cutting process is often operated by a hand crank or lever. While they are more labor-intensive, they are cost-effective and ideal for small-scale bakeries or pizzerias.

- Semi-Automatic Dough Ball Cutting Machines

Semi-automatic machines are a step ahead of manual models. They automate some aspects of the dough cutting process, such as portioning and rounding, while still requiring human intervention for dough feeding. These machines are ideal for medium-sized bakeries that need to balance efficiency and manual control.

- Fully Automatic Dough Ball Cutting Machines

Fully automatic dough ball cutting machines are designed for high-volume production. These machines are equipped with advanced technology that handles the entire process from dough feeding to ball formation and discharge. Fully automatic systems are ideal for large-scale operations, allowing bakeries to achieve maximum productivity with minimal manual effort.

- Rotary Dough Ball Cutting Machines

Rotary dough ball cutting machines are designed for large-scale operations that need to produce a high volume of dough balls quickly. These machines use a rotary mechanism to cut and form dough balls, offering increased speed and efficiency compared to traditional systems. They are typically used in industrial bakeries and pizza factories.

Reviews

There are no reviews yet.